Welding and soldering are two terms that are interchangeable in the manufacturing industry. However, while the operation of both production processes is similar, they can be distinguished in terms of sub-techniques, skill requirements, heat, etc.

Weld and sold are widely used in the automotive, electronics, construction, mechanical, and other industries. Therefore, it is important to understand the difference between these processes.

Let’s start with the main differences between these processes and move on to their advantages and disadvantages.

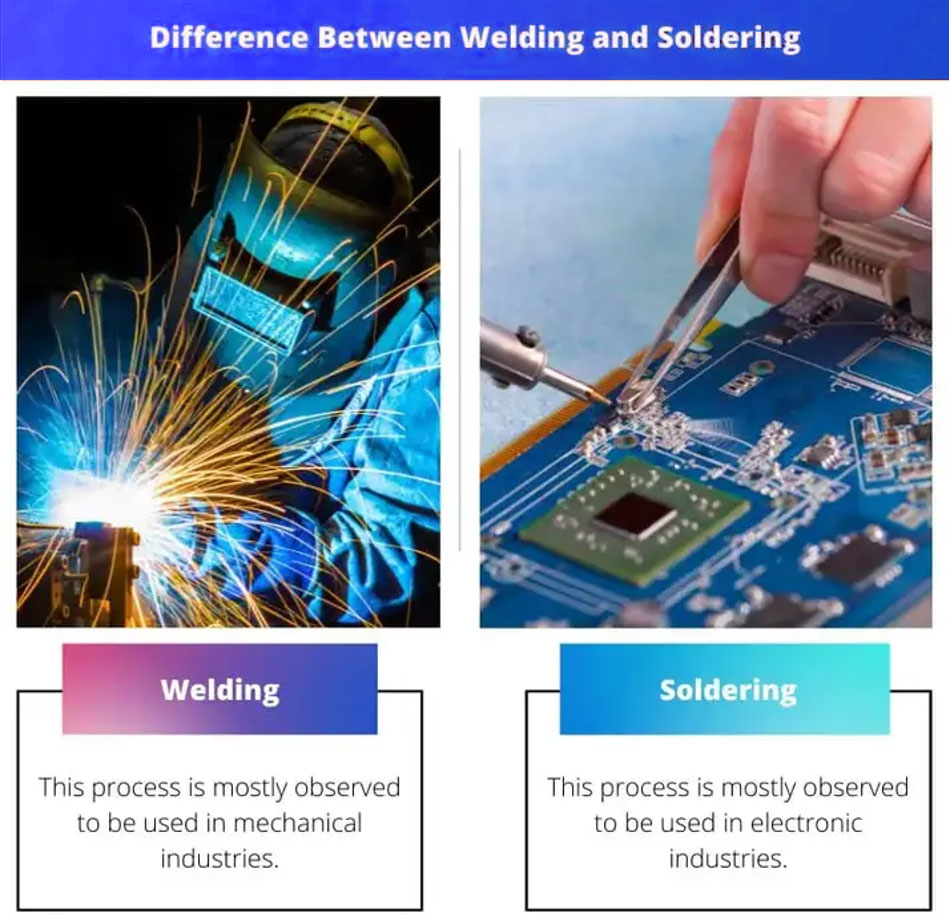

Welding vs soldering – are both fabrication methods, meaning they are used to join metal materials together using specific equipment and materials. Below are the main differences between welding and brazing:

- Strength – Welded joints are stronger than brazed joints.

- Temperature. Different metals require different temperatures to melt and form a bond.

- The steel option is typically used for welding, which may require temperatures between 3,000 and 20,000 degrees Celsius. On the other hand, brazing requires approximately 350 to 450 degrees Celsius.

- Heating – base metals are heated during the welding process to melt and form a strong bond, whereas brazing does not require base metals to be heated or melted.

- Metal properties – during welding, the base metal changes its mechanical properties due to cooling and heating. Brazing does not significantly affect the mechanical properties of the metal.

- Heat treatment. Heat treatment is a process in which the physical and chemical properties of a metal are changed by heating and cooling it. It is commonplace in welding technologies, but not in brazing.

- Qualification requirements – A welder and a brazer are professional workers who need skills and experience to perform the work they are assigned. A welder can be found in the automotive, manufacturing, and construction industries. A solderer works mainly in the electronics industry.

- Preheating – Soldering requires preheating of the parts, while welding does not require preheating of the parts.

Common types of welding and brazing methods

Welding:

- Gas metal arc

- Flux cored arc

- Shielded metal arc

- Gas tungsten arc

Soldering:

- Conventional soldering

- Soldering with silver solders

- Contact soldering

- Induction brazing

Let’s now take a look at what welding and brazing are, and discuss the advantages and disadvantages of each.

Learn more about welding

Simply put, welding can be defined as a method of joining metal parts by heating and melting the parts in contact at a specific point and cooling until a strong bond is formed.

Base metals are heated to melt, which changes the properties of the metal and therefore provides a strong connection. Speaking of complexity, welding is more complicated than brazing and requires additional technical knowledge because it involves the use of gases, flames, and electricity that need to be regulated.

In this method, the metals can be of the same property or different, plus it involves the use of equipment to perform the task. The temperature largely depends on the type of metal being welded and the type of welding, but it is usually around 3000 degrees Celsius, and in some cases much higher.

Types of welding

Welding can be divided into two main categories:

Arc welding is the use of electricity to heat and melt the base metal. It can be divided into the following categories:

- MMA/SMAW electric arc welding

- MIG welding

- TIG welding

- EGW welding

Torch welding is the use of fuel gases and oxygen to heat and melt the base metal.

Advantages and disadvantages of welding

Welding creates a joint when the base metal is heated, melted and cooled again, however it has its pros and cons, let’s take a look:

Advantages:

- Welding creates a strong connection.

- This method creates the strongest bond compared to other methods.

- No need to drill a hole in the main parts for welding.

- Dissimilar metals of different sizes and shapes can be welded.

Disadvantages:

- Requires skilled labor and good equipment.

- Uneven cooling and heating can lead to residual stresses in the welded joint.

- Welded joints are subject to vibration.

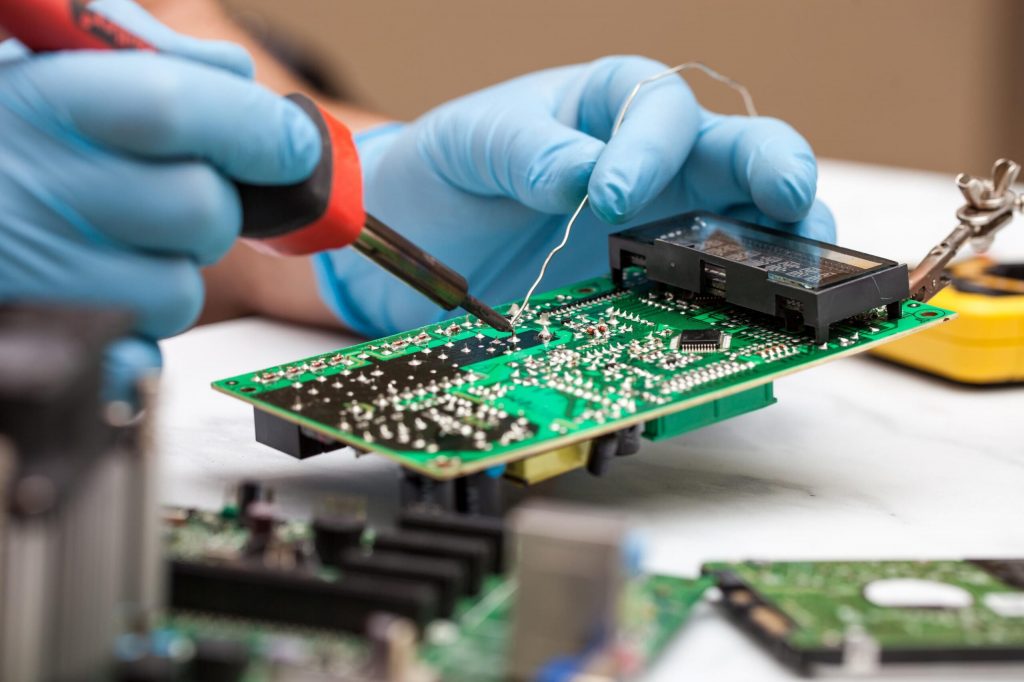

About soldering process

Brazing is a method or process of joining metals using solder. Solder is a low melting point metal alloy that is often considered the base metal for brazing.

The part or structure to be joined is not heated to the point of melting, and this is where the solder (base metal) comes into play to create the joint.

Since the melting point of the base metal is low, the temperature required by this method is as low as 448 degrees Celsius. However, the temperature can vary depending on the metal and the type of work being performed.

Brazing is widely used in the electronics industry. It is also used in the jewelry industry.

Advantages and disadvantages of soldering

Soldering is an important method in various industries and has its advantages and disadvantages. Let’s take a closer look.

Advantages:

- Soldering can work at low temperatures.

- Different materials can be easily joined.

- Residual stresses are low.

- It is not a time-consuming process.

- Brazing is simple and does not require high skills.

Disadvantages:

- The combination of materials is not very strong.

- Brazing is not suitable for assembling large structures.

- The fluxes used in the brazing process can be toxic.

Welding vs brazing: a comparison table

| CRITERIA | WELDING | BRAZING |

| Melting point | The melting point for welding is above 450 degrees Celsius. | The melting point for brazing is below 450 degrees Celsius. |

| Types | Plasma, laser and electric current. | Soldering iron and electrical resistance. |

| Deformation | Very high | Very low |

| Defects | Very likely | Very low probability of defects. |

| Preheating | Not required | Required |

| Connections | Connections have very high strength. | Solder joints have a lower strength. |

The difference between welding and brazing

Here are a few differences between welding and brazing:

- Melting point of the additive material – when brazing, the temperature is less than 450 degrees Celsius, which is roughly the same as the melting point of the base metal. When welding, it exceeds 450 degrees Celsius.

- The use of flux. Flux is a cleaning chemical that helps in the brazing process. This reagent is not required in the welding process.

- Heat source – In welding, common heat sources are electric current, plasma, electron beams, and electric arc. In the case of brazing, the heat sources are ultrasound and electrical resistance.

- Deformation – During the welding process, the material undergoes both physical and chemical changes. The degree of deformation is quite low during brazing.

- Residual deformation. During the welding process, there is a high probability that residual deformations will remain, but this does not apply to the brazing process.

Conclusion about weld vs sold.

Welding is a process of joining identical or dissimilar metals using equipment and additional materials. They fall into two main categories: arc welding and torch welding. The joints created by welding are very strong and have high durability. This method is widely used in construction, automotive, and mechanical engineering.

Brazing is the process of joining identical or dissimilar metals using solder. The main material used in brazing is solder (a metal alloy) because it has a higher melting point than brazed materials. The soldering technique is common in the electronics industry. This method is easy to use and requires less time.