Welding types – classification.

Welding types are divided based on basic physical, technical, and technological characteristics. Depending on the form of energy used to create non-detachable connections, welding methods are classified into classes. A classification has also been introduced by the standard depending on the energy source used for welding, according to which technological processes are divided into types. Such classification templates and characteristics are attributed to physical ones. Technical characteristics include: method of protecting the welding zone, degree of mechanization of the welding method, continuity of welding. Technological characteristics are usually established for each type of welding separately.

Welding types are divided based on basic physical, technical, and technological characteristics. Depending on the form of energy used to create non-detachable connections, welding methods are classified into classes. A classification has also been introduced by the standard depending on the energy source used for welding, according to which technological processes are divided into types. Such classification templates and characteristics are attributed to physical ones. Technical characteristics include: method of protecting the welding zone, degree of mechanization of the welding method, continuity of welding. Technological characteristics are usually established for each type of welding separately.

Classification of different types of welding by classes

Welding types belong to the thermal class: arc, electroslag, electron-beam, ion-beam, plasma-beam, glow discharge, light, induction, gas welding, thermite, foundry welding. Types of welding of the thermomechanical class: contact, diffusion, induction-press, gas-press, thermocompression, arc-press, slag-press, thermite-press, furnace welding. The mechanical class includes: cold, ultrasonic, magnetoimpulse, friction welding and explosion.

- Welding with electric current is divided into 2 principal classes: non-arc and arc.

Non-arc welding is often called contact. In contact welding, the electrodes supplying the current are applied directly to the metal being welded. A short but very powerful current discharge (thousands of amperes) is passed through the metal located between the raised electrodes. Melting in this case occurs only between the applied electrodes. If the electrodes are located directly opposite each other, then the welded joint turns out to be point-like. Although spot welding is not the only type of contact welding, it is the most common. Therefore, the concepts of “spot welding” and “contact welding” are often used as synonyms. The voltage of spot welding is a few volts. Therefore, contact welding is mainly used for fastening thin-sheet metal. For example, in car manufacturing.

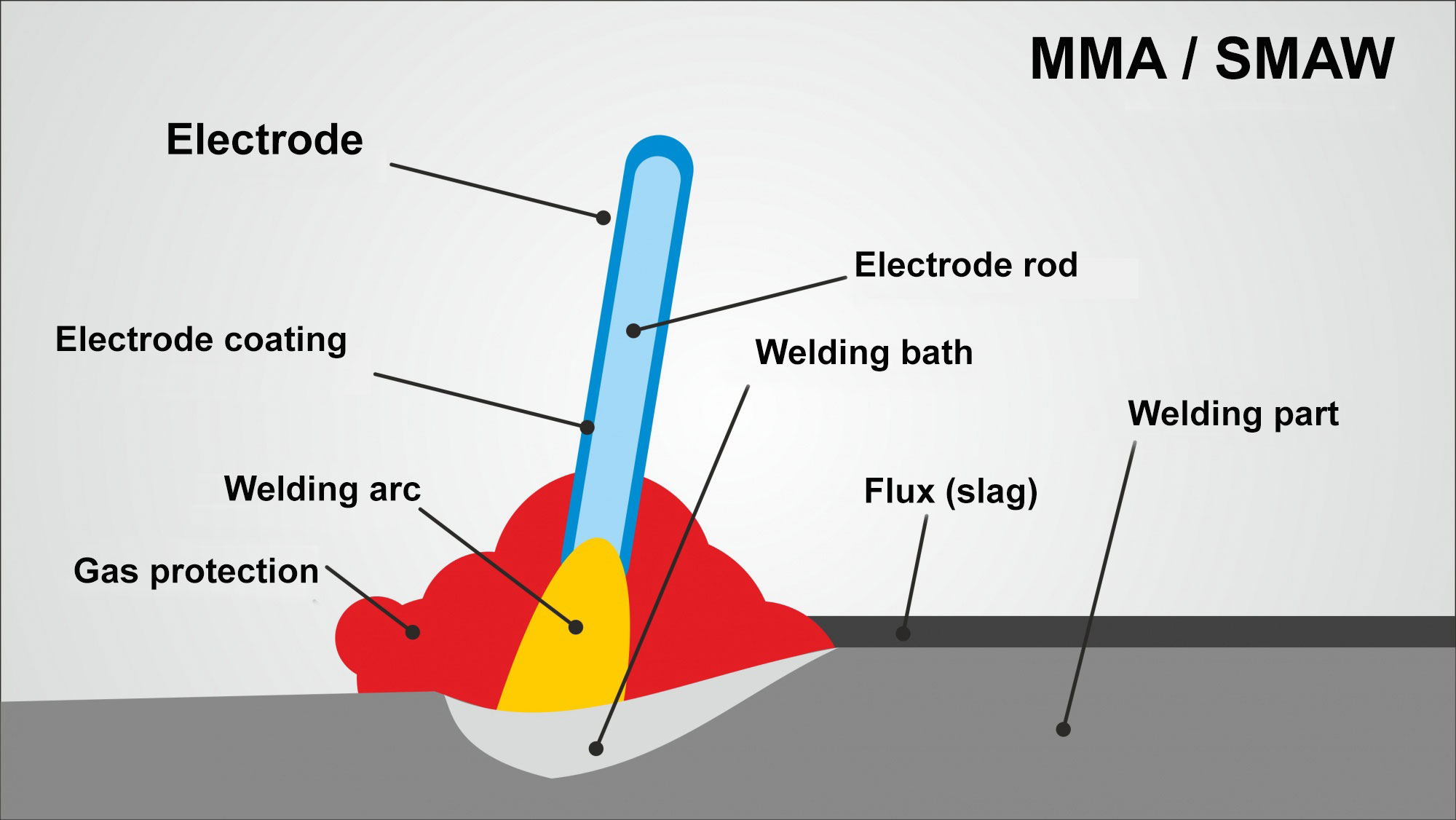

In construction, electric arc welding has become much more widespread. During welding, there is a small gap between the current source (electrode) and the welded metal, which is filled with an electric arc. It is mistakenly assumed that this is an air gap. This is a gap of ionized gas that conducts current. Arc welding, as we imagine it today, is impossible without gas. It’s just that gas can be supplied from a separate cylinder, or it can be formed as a result of the burning of the electrode coating.

The most common technologies in construction are:

- MMA / SMAW (This welding method is known as Manual Metal Arc (MMA) or (SMAW) Shielded Metal Arc Welding )

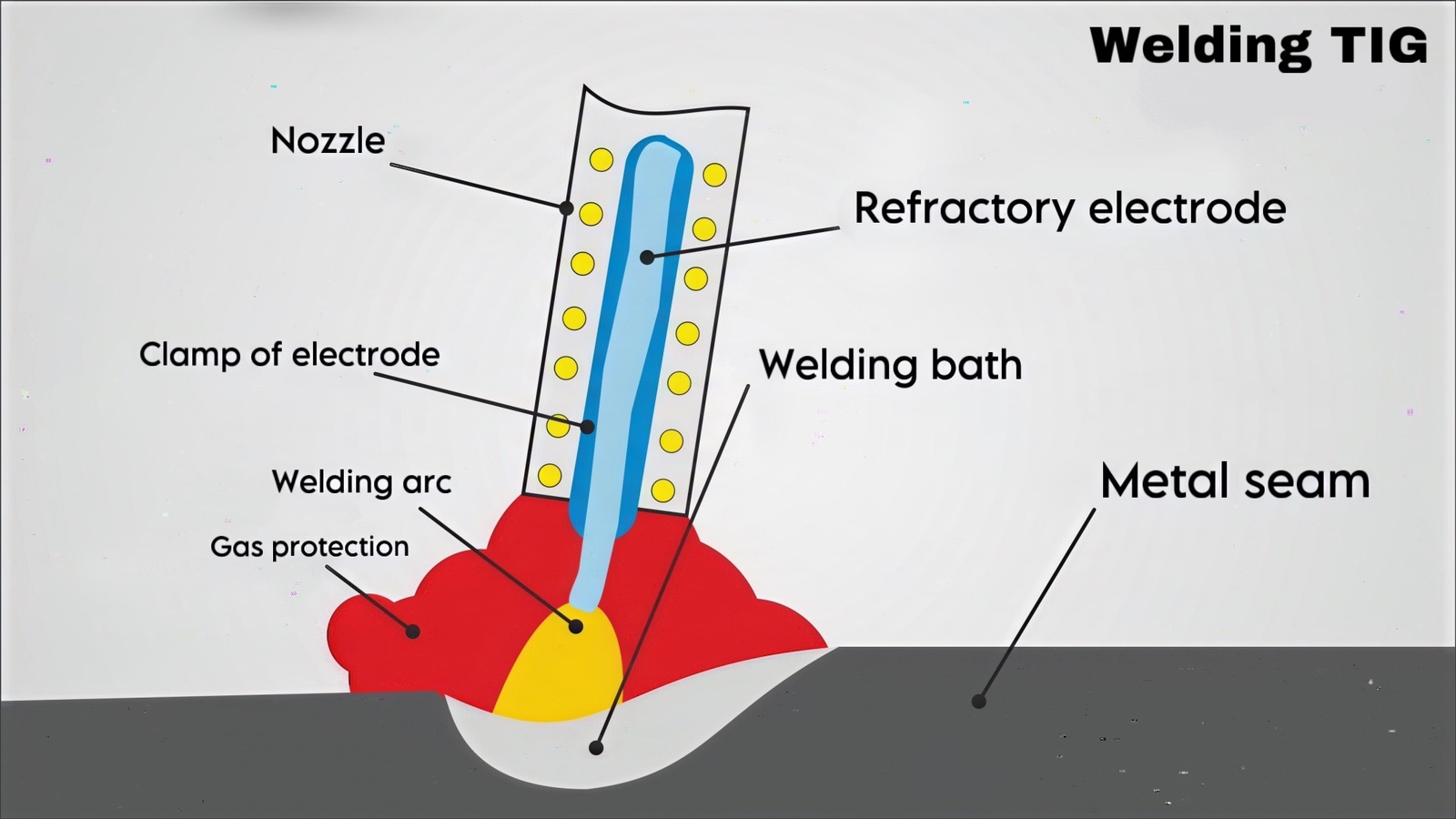

- TIG (argon-arc)

- MIG-MAG (semi-automatic, wire).

SMAW / MMA welding type

Both terms are used to describe the same welding method. The term ‘MMA’ is more commonly used in Europe and other regions, while ‘SMAW’ is more prevalent in the USA. It’s important to note that regardless of which term you use, they both describe the same welding process.”

The popularity of this type of welding is due to the absence of the need to carry a gas cylinder with you. The coating of the electrode is the “frozen” gas cloud. As soon as the electrode touches the metal and the short-circuit current obtained melts the metal of the electrode, the coating around it will also melt. The gas cloud will provide a conductive ionized environment for the arc and protect the melting metal from oxygen access.

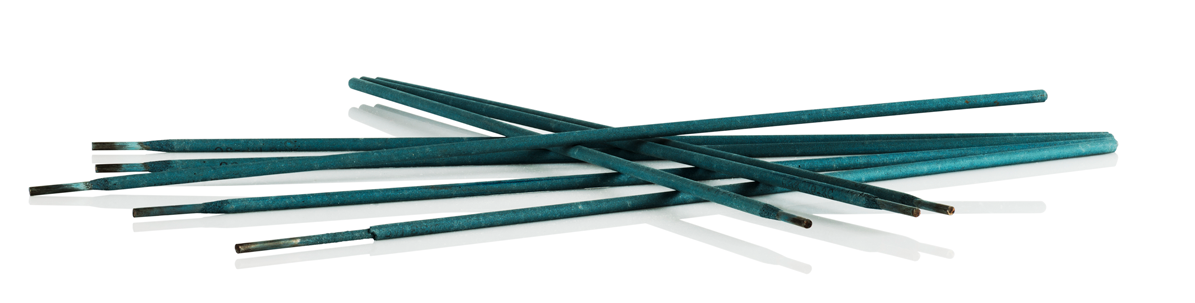

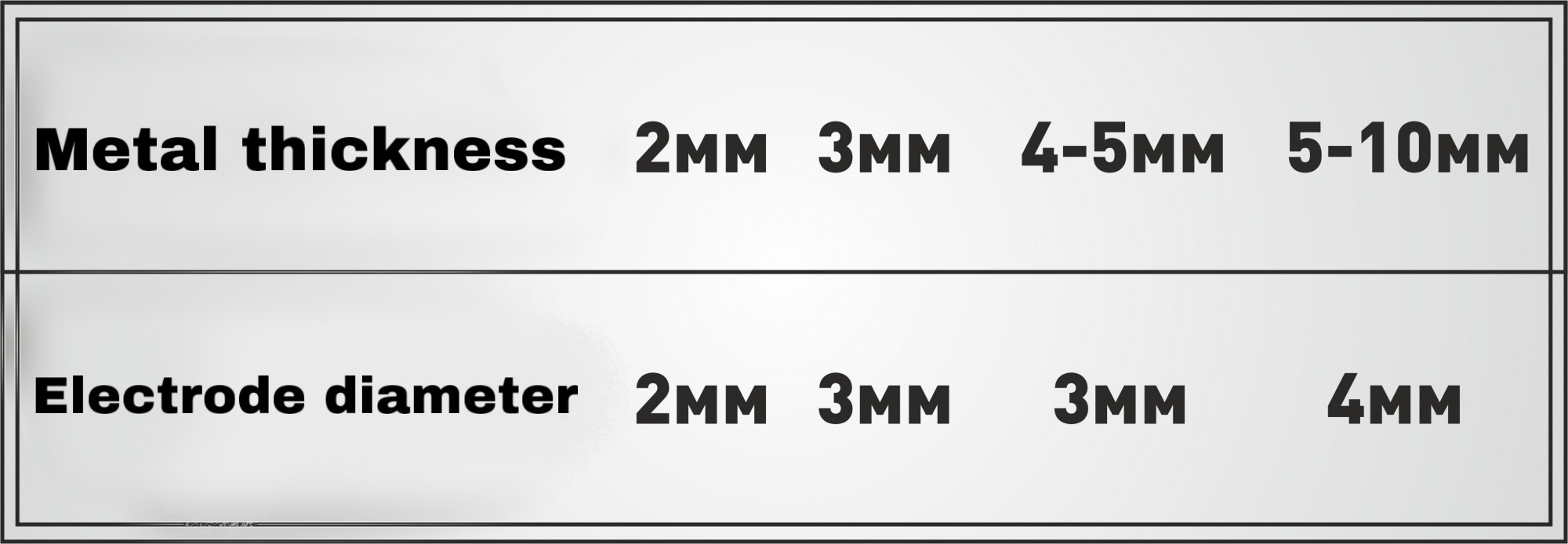

Electrodes are selected by the type of metal and diameter. The type of metal is important because during the work the metal of the electrode rod drop by drop passes into the welded metal and alloys with it. For a strong connection, the metal of the electrode rod and the welded metal must be identical. The packaging of the electrodes always indicates for which metals these electrodes are suitable.

Tig welding type

TIG welding is primarily used by professionals and advanced users, almost exclusively in non-construction fields. TIG provides neater seams but significantly lags behind MMA / SMAW in productivity and ease of use.

For example, many “amateurs”, having honed their skills on MMA machines, feel frustration from failures in their first experience with TIG. It turns out that, unlike MMA / SMAW, it is not easy to ignite an arc with a TIG machine unless it is equipped with a device such as an oscillator. (And practically all “2 in 1” machines are not equipped, of course). The welder sparks with a tungsten electrode – there is a spark, but the arc does not rise. But here an experienced welder puts a piece of coal under the electrode – and the arc went without problems. It is no coincidence that in retail sales, specialized TIG machines rarely exceed a share of 1%. Separate mention in TIG welding deserves machines with the ability to switch to Separate mention in TIG welding deserves machines with the ability to switch to alternating welding current mode, so-called AC / DC. These machines are the main equipment for welding aluminum. They mostly make up this very 1% of TIG in retail sales of welding equipment.

Separate mention in TIG welding deserves machines with the ability to switch to Separate mention in TIG welding deserves machines with the ability to switch to alternating welding current mode, so-called AC / DC. These machines are the main equipment for welding aluminum. They mostly make up this very 1% of TIG in retail sales of welding equipment.

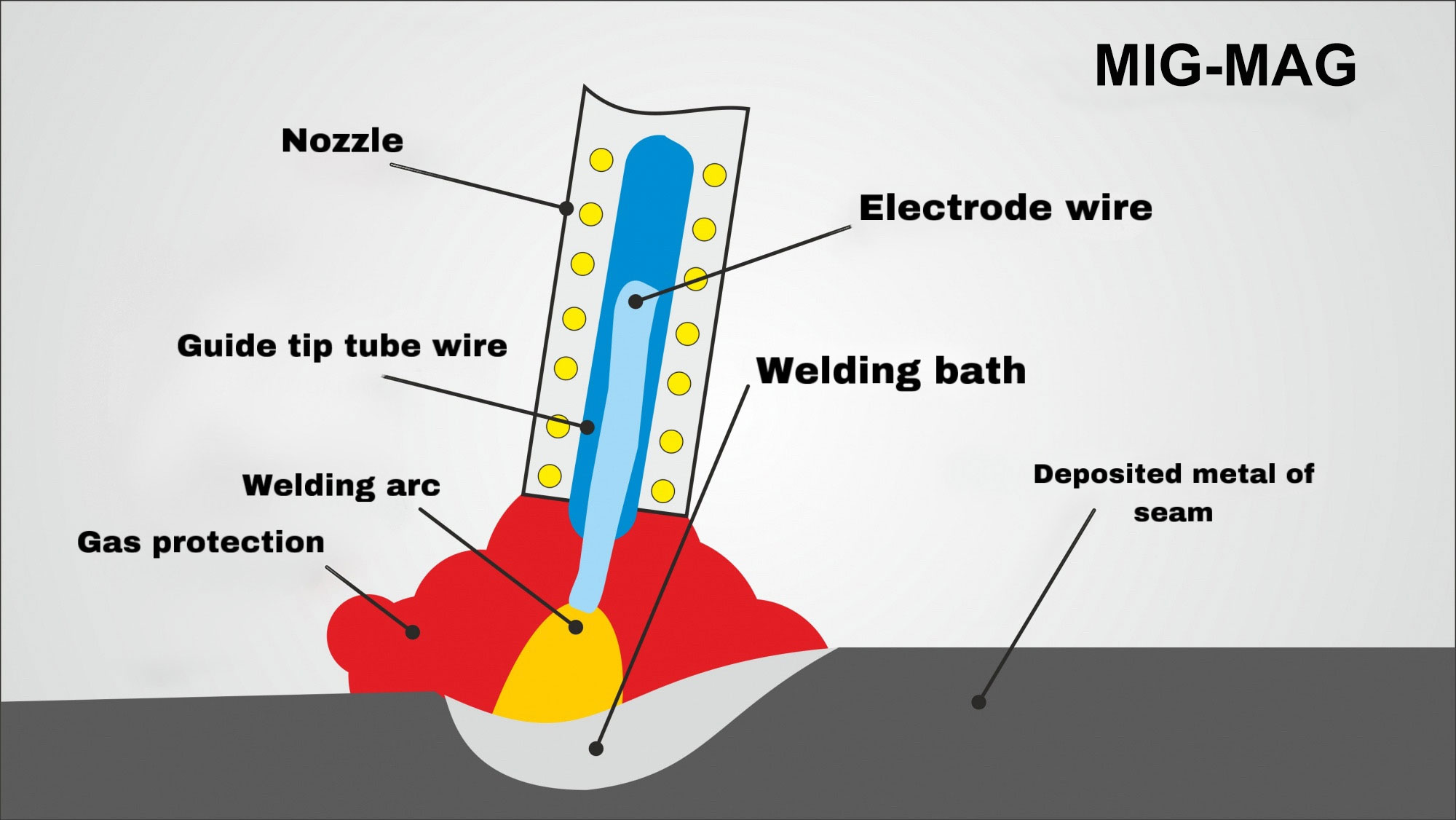

MIG-MAG welding type

Semi-automatic wire welding is mainly used for welding sheet metal. Therefore, its main area of application is body repair, as well as the construction of structures from black sheet metal. The use of wire instead of consumable electrodes greatly increases productivity. On household machines, coils with a capacity of 1 and 5 kg are used, and on professional ones – 5 or 15 kg.

The wire can be used both ordinary (without coating) and with a coating (so-called flux). In the first case, the use of a gas cylinder is mandatory (GAS mode). In the second, a balloon is not needed (NO GAS). Despite the fact that working without a balloon is more convenient, in sales, the wire without coating leads by a large margin. The reason is banal: it is much cheaper than flux. In addition, many professionals believe that the neatness of seams in the gas environment from a balloon is higher.

Despite the fact that this type of welding also belongs to electric arc, the principle of the device in MIG-MAG fundamentally differs from the principles of MMA and TIG. In MMA and TIG, it is important to maintain the stability of the current, regardless of the fluctuations of the electrode, in MIG-MAG it is important to maintain the stability of the arc voltage. And the welding current strength in MIG-MAG machines is a conditional indicator (although by habit, developed in SMAW/MMA, most are guided by it). The welding current strength in MIG-MAG will depend on the set voltage, the diameter of the wire used, the gas used, and the wire feed speed. So making a semi-automatic MIG-MAG out of an MMA/SMAW machine by adding a wire feed block and a torch will not work.